Aluminium Plate 5251

Manufacturers across Europe and Asia are increasingly specifying Aluminium Plate 5251 in new procurement cycles this quarter, citing a combination of corrosion resistance, formability, and cost-performance advantages for medium-strength applications. Industry participants say demand is rising in marine-adjacent fabrication, transport components, and general sheet metal work as companies pursue lightweighting and longer service life without moving to higher-cost alloys.

What is driving the renewed focus on 5xxx-series aluminium?

Market analysts link the shift to three converging trends: tighter durability requirements in coastal infrastructure, a broader push to reduce vehicle weight, and greater scrutiny of lifecycle costs. While 6xxx series alloys remain common for extrusion-heavy designs, fabricators working with plate and sheet are re-evaluating 5xxx series options where weldability and saltwater resistance matter.

Procurement teams are looking beyond spot price and asking what the material does over 10 to 15 years, said a simulated metals market analyst at a global consultancy. Thats where EN AW-5251 stands outespecially for formed panels and welded assemblies that see moisture or marine exposure.

Material profile: where Aluminium Plate 5251 fits

Aluminium Plate 5251 is a magnesium-containing alloy in the 5xxx family, commonly selected when users need a balance of:

Good corrosion resistance, including performance in humid or mildly aggressive environments

High formability for bending and shaping operations

Weldability for fabricated structures and assemblies

Moderate strength, often specified with H tempers depending on end-use

Engineers note that the alloys practical value is not only in its mechanical properties but also in production versatility: it is regularly sourced as plate or sheet for laser cutting, CNC routing, bending, and welding workflows.

Typical applications being reported

Supply-chain contacts point to growing usage in:

Boat and dock-adjacent components (non-structural to semi-structural)

Vehicle body panels, covers, and interior reinforcements

Machinery guarding, enclosures, and fabricated housings

Architectural cladding and formed trims where corrosion resistance is prioritized

Although some marine projects still default to higher-magnesium grades, several fabricators interviewed said Aluminium Plate 5251 is being shortlisted for value-engineered designs where cost and manufacturability are critical.

Supply, pricing, and lead times: cautious optimism

Service centers report that lead times for common gauges have stabilized compared with prior volatility, though buyers remain cautious about availability of specific tempers and tight thickness tolerances. One simulated sales director at a European stockholder said customers are increasingly requesting documentation packagesmaterial test certificates, traceability records, and compliance statementsparticularly for transportation and infrastructure projects.

Stock is more predictable than it was, but customers want consistency: same coil/plate source, repeatable forming behavior, and reliable surface quality, the executive said. In that context, 5251 is popular because its forgiving in fabrication and holds up well in service.

Data insight: lifecycle cost is shaping decisions

A simulated internal review from a mid-sized OEM showed that switching from a coated carbon steel panel to 5xxx-series aluminium reduced corrosion-related maintenance events by an estimated 2030% over a multi-year operating window, despite a higher initial material cost. While results vary by environment and design, similar calculations are increasingly appearing in purchasing discussions.

Manufacturing implications: fabrication and quality control

Fabricators say adoption is also influenced by shop-floor realities. For many operations, Aluminium Plate 5251 performs well in bending and forming, but quality outcomes still depend on correct process settings:

Tooling selection and bend radii to prevent surface marking

Weld procedure qualification to manage heat input and distortion

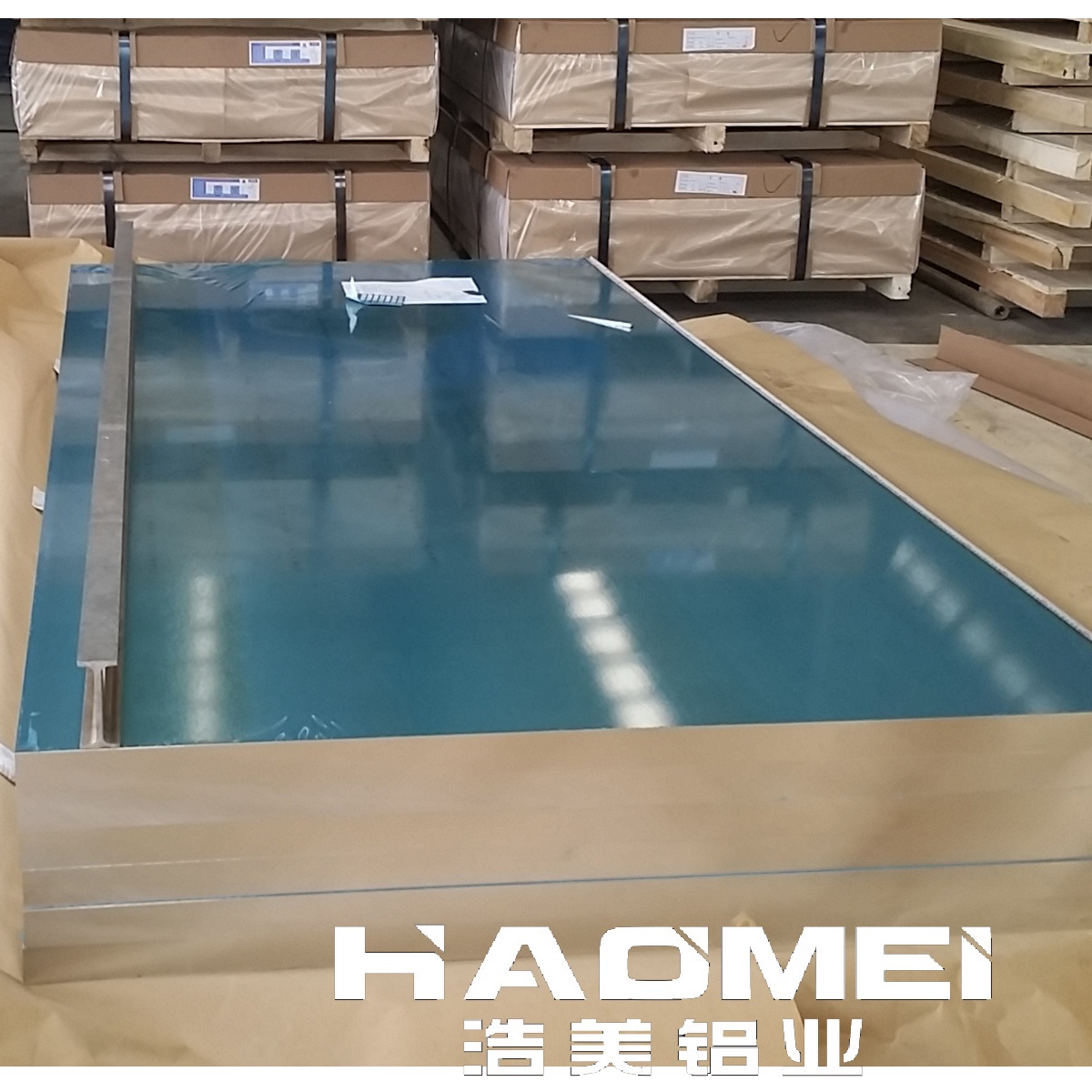

Surface protection and packaging to avoid transport scratches

Industry sources also noted more frequent use of protective films and upgraded palletization for aluminium plate and sheet shipments, reflecting customer sensitivity to cosmetic defects in visible panels.

Outlook: what to watch next

Analysts expect near-term demand to track activity in transportation builds, marine maintenance cycles, and light industrial fabrication. If sustainability reporting continues to influence supplier selection, 5xxx-series alloys could benefit further due to recyclability and potential reductions in operational emissions through lightweighting.

However, buyers are also advised to validate specifications carefullyparticularly temper, thickness tolerance, and surface finishsince application requirements can vary widely across sectors.

Conclusion

As manufacturers weigh durability, fabrication efficiency, and total cost of ownership, Aluminium Plate 5251 is emerging as a pragmatic choice for corrosion-resistant plate and sheet applications. The near-term market is expected to reward suppliers that can offer consistent quality, strong documentation, and packaging that protects surface finish from warehouse to workshop.

Meta description (150160 chars): Aluminium Plate 5251 is gaining traction for corrosion resistance, weldability, and formability, supporting lightweighting across marine, transport, and fabrication.