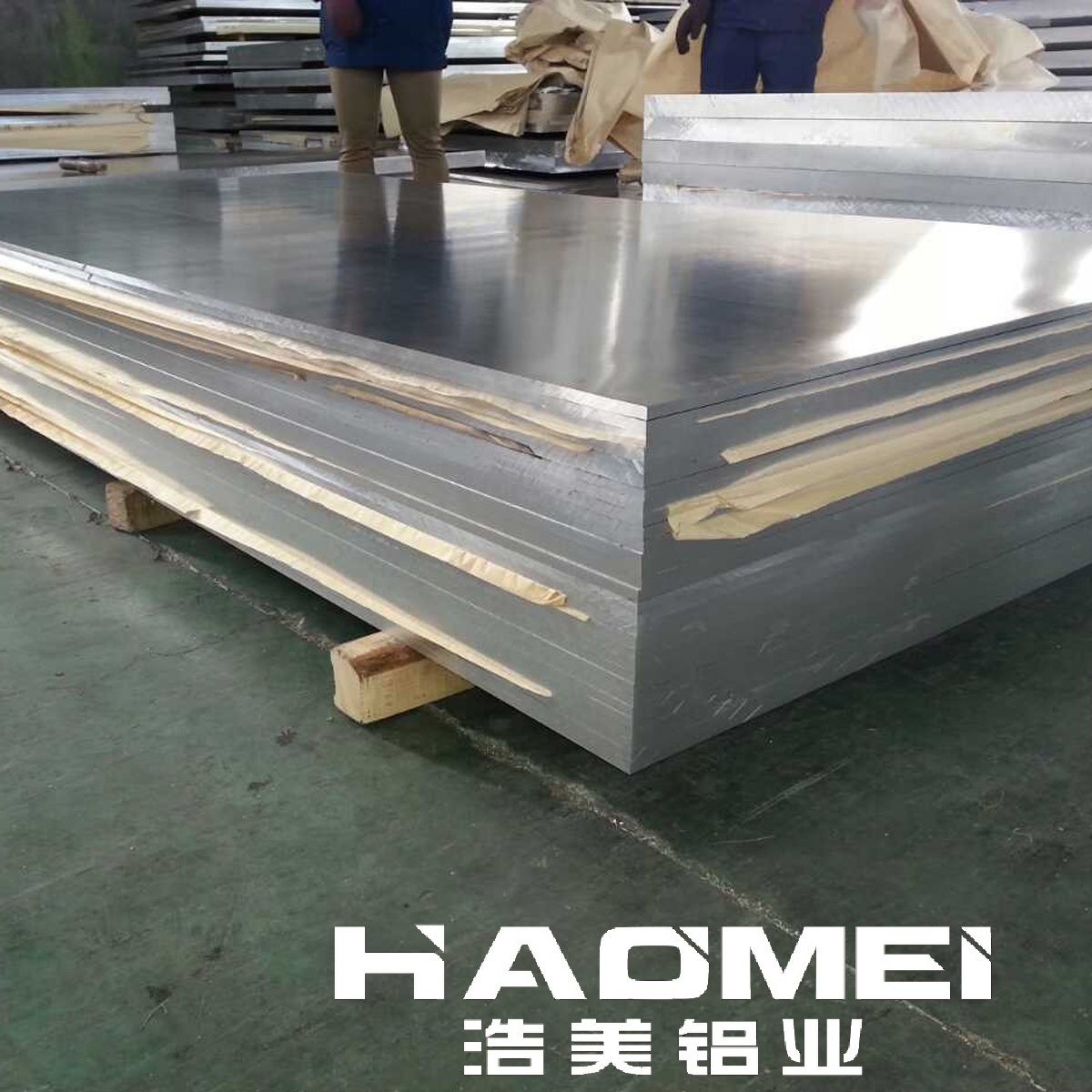

Aluminium Plate 50mm

When your project needs rigidity, reliable flatness, and clean machining, a 50mm aluminium plate is a practical, high-performance choice. This thickness is widely used for CNC machining, tooling, fixtures, base plates, and structural components where thinner sheets may flex or distort.

Our Aluminium Plate 50mm is supplied with a focus on consistent thickness, smooth surface quality, and stable performancehelping you reduce machining time, improve dimensional accuracy, and get better final-part results.

Key Parameters (Typical Supply Range)

Final availability may vary by alloy, temper, and required tolerance. Contact us for a quick quote and stock confirmation.

Thickness

50mm ( tolerance available on request)

Material / Alloy Options

6061 / 6082 (popular for machining, strength, corrosion resistance)

5083 (excellent corrosion resistance; marine/industrial use)

7075 (high strength for demanding mechanical applications)

3003 (general forming; usually used in thinner gauges, but available on request)

Temper (Common)

T6 / T651 (typical for 6061 machining plate)

Other tempers available depending on alloy

Surface & Finish

Mill finish (standard)

Protective film (optional)

Precision milling / blanchard grinding (optional)

Size & Cutting

Standard sheets/plates or custom cut-to-size

Cutting options (depending on service): saw cut, CNC cut, milling for tighter tolerance

Quality Options

Certificates: Mill Test Certificate (MTC/EN10204 3.1) available

RoHS/REACH compliance available (upon request)

Purpose & Applications (Where 50mm Aluminium Plate Excels)

A 50mm aluminum plate is commonly selected when the design requires a stiff, thick, machinable block-like plate without moving to steel.

Typical uses include:

CNC machining parts (precision components, housings, brackets)

Jigs & fixtures (stable platforms, locating plates, tooling bases)

Machine base plates and equipment mounting plates

Molds and tooling plates (depending on alloy/flatness requirements)

Industrial frames and supports where weight reduction matters

Marine and outdoor structures (especially 5083)

Packaging (Safe Delivery for Heavy, Thick Plates)

We pack 50mm thick plates to minimize scratches, edge damage, and transport shifting.

Standard packaging may include:

Surface protection (film/paper) where applicable

Strong export-grade wooden pallet/crate support

Corner/edge protection for impact resistance

Steel/plastic strapping for stability

Moisture protection for long-distance shipping

Clear labels (size, alloy, heat/lot, weight)

Advantages (Why Buyers Choose This 50mm Aluminium Plate)

1) High Strength-to-Weight Ratio

Get strong structural performance while keeping parts lighter than steel, improving handling and reducing shipping and assembly load.

2) Excellent Machinability (Especially 6061/6082)

Clean chip formation and stable cutting behavior help reduce tool wear and improve finishideal for CNC milling, drilling, tapping, and boring.

3) Corrosion Resistance

Many aluminum alloys offer reliable corrosion resistance for workshops, outdoor environments, and industrial settings.

4) Dimensional Stability for Thick Sections

50mm thickness delivers rigidity that helps reduce flexing during machining and assembly, supporting better tolerances.

5) Custom Cutting Reduces Waste

Order plate cut to your size to save time, reduce scrap, and speed up production.

FAQ Aluminium Plate 50mm

Q1: Which alloy is best for CNC machining in 50mm thickness?

6061-T6/T651 is the most common choice due to its balance of strength, machinability, and corrosion resistance. For higher strength, consider 7075; for marine environments, consider 5083.

Q2: Can I order custom sizes instead of full sheets?

Yes. We offer cut-to-size options. Provide your required length width, quantity, and tolerance/flatness needs.

Q3: What tolerance can you supply for 50mm aluminium plate?

Tolerance depends on alloy, processing route, and whether you choose standard mill tolerance or precision milled/ground supply. Tell us your application and tolerance needs for the best recommendation.

Q4: Do you provide material certificates?

Yes, Mill Test Certificates (MTC/EN10204 3.1) can be provided upon request.

Q5: How is the plate packaged to avoid damage during shipping?

Thick plates are secured with pallet/crate support, strapping, edge protection, and optional surface protection, helping prevent movement, dents, and scratches.

Q6: Is 50mm aluminium plate suitable for welding?

Many alloys such as 6061 and 5083 are weldable (process and filler selection matter). If the part will be heavily welded, we can recommend an alloy better suited to welding and corrosion performance.

Ready to Order Aluminium Plate 50mm?

Share your alloy preference (e.g., 6061/5083/7075), plate size, quantity, and any tolerance/flatness requirements. Well help you match the right thick aluminum plate to your application and provide a fast quotation.